Unlocking Business Potential with Cutting-Edge Printing Solutions and Electronics Innovation

In today’s hyper-competitive marketplace, businesses must leverage the latest technological advancements to stand out and meet evolving customer demands. At the forefront of this revolution are innovative printing services and advanced electronic devices, which together create a powerful synergy for business growth. Whether you are in the manufacturing sector, retail, healthcare, or events management, harnessing these technologies can significantly enhance your operational efficiency and brand perception.

Understanding the Role of Advanced Printing Services in Modern Business

Printing is no longer just about producing simple labels or documents; it has evolved into a strategic tool for branding, inventory management, security, and customer engagement. The rise of high-quality, durable printing solutions enhances product presentation, reduces counterfeit risks, and improves overall workflow. Companies like durafastlabel.com exemplify this shift by offering premium printing services designed to meet diverse business needs.

Benefits of Premium Printing Services for Your Business

- High Durability: Durable labels withstand harsh environmental conditions, reducing replacement costs and enhancing brand image.

- Customizability: Advanced printing techniques enable personalized branding, QR codes, barcodes, and detailed graphics.

- Security Features: Incorporate tamper-evident elements and holograms to prevent counterfeiting and fraud.

- Cost Efficiency: Large-volume printing at reduced per-unit costs improves profit margins.

- Speed and Precision: Fast turnaround times with high-resolution outputs ensure timely product launches and updates.

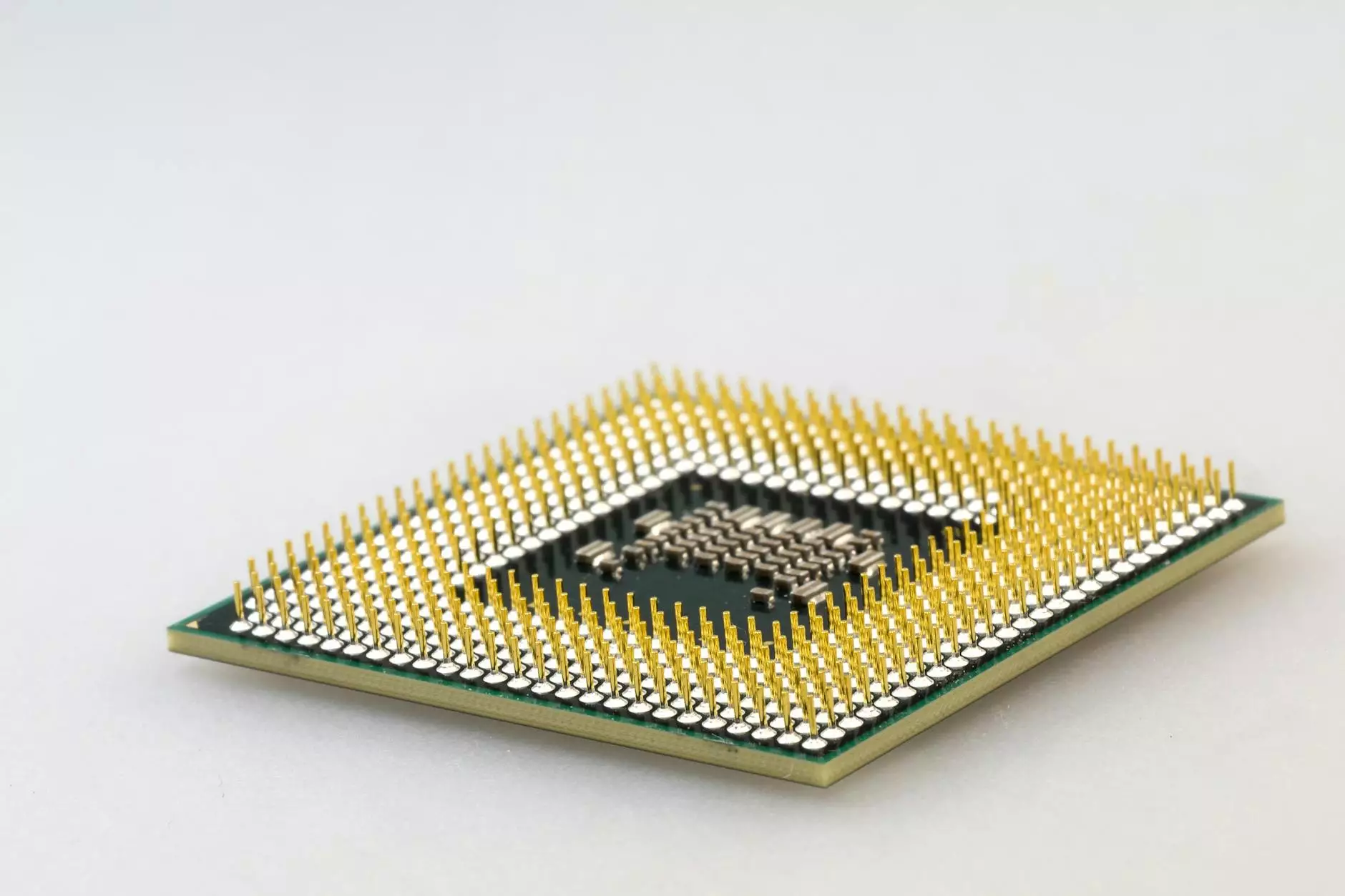

The Intersection of Printing Innovation and Electronics in Business Operations

Electronics are fundamental in automating and optimizing printing processes. From wristband printing machines to integrated barcode systems, electronics facilitate seamless, high-volume, and personalized production. The adoption of electronic components within printing equipment improves accuracy, reduces waste, and enables remote management.

How Electronics Elevate Printing Capabilities

- Automation: Automated feeding and cutting mechanisms streamline high-speed production lines.

- Connectivity: IoT-enabled printers connect to networks for remote monitoring and maintenance, minimizing downtime.

- Precision Control: Electronic controls ensure complex designs and colors are rendered with accuracy.

- Data Integration: Linking printing devices with inventory and CRM systems improves real-time tracking and inventory management.

The Significance of the wristband printing machine in Security, Events, and Healthcare

Among electronic printing innovations, the wristband printing machine stands out as an essential tool for multiple industries. Its ability to produce customized, durable wristbands rapidly makes it invaluable for healthcare, event management, and security applications.

Why Choose a wristband printing machine? Key Advantages

- Custom Branding: Easily incorporate logos, event details, or personal information for branding and identification.

- Durability: Made with waterproof, sweatproof, and tear-resistant materials suitable for extended wear.

- Fast Production: Capable of printing large batches efficiently, critical for mass events or hospital admissions.

- Security Features: Embed barcodes, QR codes, or RFID chips to track access or patient details securely.

- User-Friendly Operation: Simplified interface and automated routines lower training requirements and increase productivity.

How The Wristband Printing Machine Works: Technology and Process

The wristband printing machine relies on cutting-edge electronic control systems and specialized printing technology like thermal transfer or direct thermal printing. These machines are designed for high-speed operations, capable of producing hundreds to thousands of wristbands per hour with impeccable quality.

The process typically involves:

- Design Preparation: Using software to create customized templates with logos, text, and security features.

- Material Selection: Choosing suitable wristband substrates like plastic, Tyvek, or silicone based on application requirements.

- Printing: Automated feeding of materials into the machine, which precisely prints and cuts wristbands.

- Quality Check: Post-production inspection, often aided by sensors and electronic controls, to ensure compliance with quality standards.

- Distribution: Sorted and packaged automatically for dispatch or immediate use.

Integrating Printing and Electronics for a Smarter Business Ecosystem

The future of business lies in integration. Combining printing services with advanced electronics technologies such as IoT, AI, and RFID transforms traditional workflows into intelligent systems. For example, connecting your wristband printing machine with inventory databases allows instant updates and real-time tracking, enhancing transparency and efficiency.

Key Strategies for Seamless Integration

- Invest in IoT-enabled Devices: Enable remote diagnostics, updates, and maintenance for minimal downtime.

- Leverage Data Analytics: Track printing patterns, inventory levels, and operational metrics for optimization.

- Implement Cloud-based Management: Centralize control over multiple printing units and electronic systems for streamlined management.

- Prioritize Security: Use encrypted connections and secure hardware to protect sensitive data.

Choosing the Right Printing Equipment for Your Business Needs

Selecting the optimal wristband printing machine or other printing equipment depends on your specific application, volume, and budget. Basic models suit small-scale needs, while industrial-grade machines are designed for enterprise-level manufacturing.

Factors to Consider When Selecting a Printing System

- Production Volume: Estimate daily output to determine the necessary speed and capacity.

- Material Compatibility: Ensure the printer can handle preferred substrate types.

- Software Compatibility: Check for ease of integration with existing systems.

- Security Features: Consider printers with built-in security options for sensitive applications.

- Cost of Operation: Include maintenance, consumables, and energy consumption in your budget planning.

Future Trends in Business Printing and Electronics Technologies

The horizon reveals exciting advancements shaping the future of business printing and electronics:

- Smart Labels and Packaging: Incorporating NFC and RFID for enhanced tracking and interactive customer experiences.

- AI-powered Printing Systems: Automating design, error detection, and predictive maintenance for maximum efficiency.

- Nanotechnology-enhanced Materials: Developing ultra-durable and eco-friendly substrates for sustainable branding.

- Integrated IoT Networks: Creating interconnected ecosystems where all devices communicate seamlessly for optimized operations.

Conclusion: Embrace Innovation to Propel Your Business Forward

In a rapidly evolving digital and physical landscape, embracing advanced printing technology combined with innovative electronic solutions such as the wristband printing machine is essential for maintaining competitive advantage. From enhancing brand image to improving operational agility and security, these tools empower businesses to deliver superior value to their customers.

By partnering with trusted providers like durafastlabel.com, your business can access high-quality printing services, cutting-edge machinery, and expert support to implement these transformative solutions. Invest today in the future of your enterprise—where excellence in printing and electronics opens doors to unlimited possibilities.